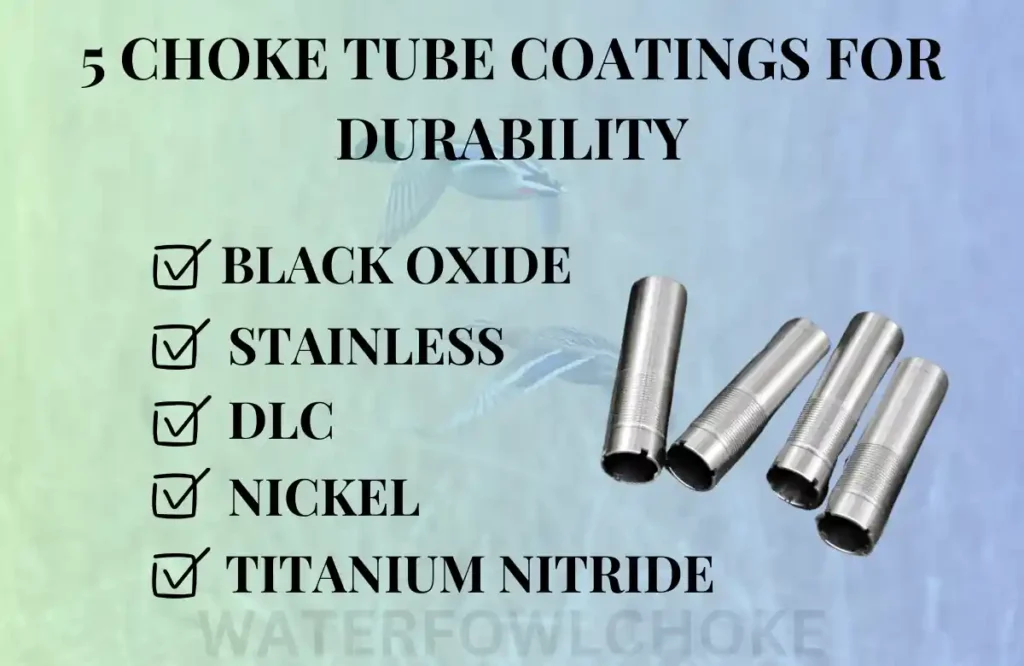

To enhance the durability and performance of shotgun choke tubes, various coatings are applied. The most common choke tube coatings are black oxide, stainless steel, diamond-like carbon (DLC), nickel, and titanium nitride.

Black Oxide Coating

Black oxide coating is a popular choice for choke tubes due to its corrosion resistance and aesthetic appeal. This coating provides a sleek, black finish, offering excellent durability against rust and wear. The black oxide coating also helps reduce glare, ensuring a stealthy appearance in the field.

Black oxide, also known as blackening or gun bluing, is a surface treatment applied to metal objects, including choke tubes. It involves a chemical conversion process that creates a black oxide layer on the surface of the metal. The black oxide coating not only provides a visually appealing black finish but also offers several functional benefits like reducing glare and improving aesthetics.

![]() Briley offers several choke tubes with black oxide coatings.

Briley offers several choke tubes with black oxide coatings.

Stainless Steel

Stainless steel is highly regarded for its exceptional durability and resistance to corrosion. Choke tubes made with stainless steel offer superb longevity, making them suitable for heavy use in various environmental conditions. This material is known for its high strength and ability to withstand extreme temperatures.

Stainless steel is a type of steel alloy that contains a high proportion of chromium (at least 10.5%). This chromium content gives stainless steel its unique properties, including resistance to corrosion, staining, and rust.

![]() Carlson’s offers several options for stainless steel choke tubes.

Carlson’s offers several options for stainless steel choke tubes.

Diamond-Like Carbon (DLC) Coating

DLC coating is a cutting-edge technology used in choke tubes to enhance their hardness and durability. This thin film coating, composed of carbon-based materials, provides excellent wear resistance and low friction. The DLC coating also offers enhanced protection against corrosion and chemical damage.

Diamond-Like Carbon (DLC) is a type of carbon coating that exhibits properties similar to those of diamond. It is a thin film coating composed of carbon atoms arranged in a diamond-like structure, hence the name.

![]() Beretta offers several options for DLC coated choke tubes.

Beretta offers several options for DLC coated choke tubes.

Nickel Coating

Nickel coating provides an added layer of protection to choke tubes, increasing their resistance to corrosion and wear. This coating exhibits a smooth and attractive silver appearance. Choke tubes with a nickel coating are known for their longevity and ability to withstand harsh shooting conditions.

Nickel is a chemical element with the symbol Ni and atomic number 28. It is a silvery-white lustrous metal that belongs to the transition metals group. Nickel has several important properties that make it useful in various applications.

In the context of choke tubes, nickel is often used as a coating or plating material. Nickel plating involves the deposition of a layer of nickel onto the surface of a substrate, such as steel.

![]() Benelli offers several options for Nickel coated choke tubes.

Benelli offers several options for Nickel coated choke tubes.

Titanium Nitride (TiN) Coating

Titanium nitride (TiN) is a hard, thin-film coating that is commonly used in various industrial applications, including firearm components such as choke tubes. It is a compound made of titanium and nitrogen, with a chemical formula of TiN.

TiN coating is widely recognized for its exceptional hardness and durability. Choke tubes with TiN coating offer superior wear resistance and exhibit a striking gold-colored finish. This coating provides excellent corrosion resistance and maintains its integrity even under high-velocity shooting scenarios.

![]() Browning offers the Diana Choke tube with Titanium Nitride coating.

Browning offers the Diana Choke tube with Titanium Nitride coating.

What is the best choke tube coating?

Among the various choke tube coatings, Diamond-Like Carbon (DLC) coating stands out as one of the best options. DLC coating combines exceptional hardness, low friction, and excellent corrosion resistance. Its advanced properties ensure prolonged durability and reliable performance even in demanding shooting conditions. Additionally, the DLC coating provides an attractive and sleek appearance.

![]() Choke Tube Coating Durability

Choke Tube Coating Durability

- Diamond-Like Carbon (highest)

- Titanium Nitride

- Black Oxide Coating

- Nickel

- Stainless Steel

Choke tubes without coatings

While coated choke tubes offer numerous benefits, it’s important to note that not all choke tubes come with coatings. Some choke tubes are made from high-quality materials such as stainless steel or titanium, which inherently possess corrosion resistance and durability. However, it’s essential to ensure proper maintenance and periodic cleaning of non-coated choke tubes to prevent rust and maintain their performance.

Bottom Line: Coatings Make Chokes More Durable

Selecting the right choke tube coating plays a crucial role in enhancing durability and optimizing performance. Choke tubes with black oxide, stainless steel, DLC, nickel, and TiN offer varying degrees of corrosion resistance, wear resistance, and aesthetic appeal.

When choosing a choke tube coating, consider the specific shooting conditions and personal preferences to ensure maximum longevity and reliability. And if you have to choose between chokes that are coated and those that are not, always choose coated.

Was this helpful?

![]()

Search Chokes by Gauge

Related

- How often should you clean your firearm?

- Fixes for choke tubes that won’t sit flush

- Top reasons why your choke tube is underperforming

- How often should you replace a choke tube?

- Choke tube cleaning tips and maintenance

Latest Posts